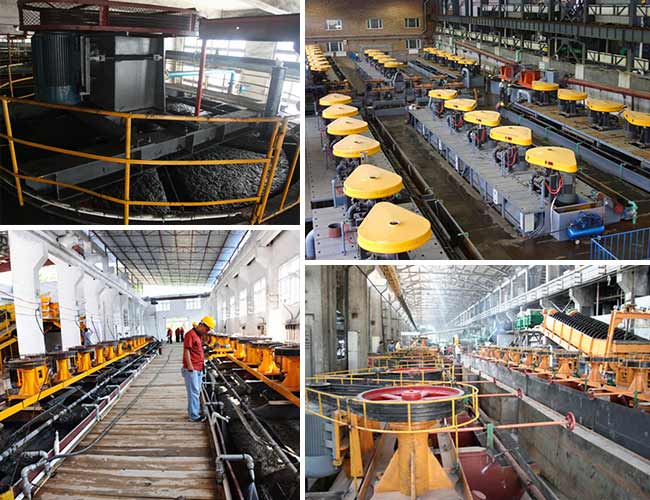

Flotation process flow

Reverse flotation includes rough flotation and clean flotation, through which ilmonite iron ore will be greatly upgraded.

Reverse flotation includes rough flotation and clean flotation, through which ilmonite iron ore will be greatly upgraded. The iron concentrate obtained is of 56.73% in content. The middlings return to magnetic flotation, forming a close-circle process.

The full set of machines of iron ore beneficiation are jaw crusher, hammer crusher, roll crusher, impact crusher, vertical crusher, cone energy efficient ball bearing, vibration screen, automatic anti-sand spiral classifier, high-performance energy-saving flotation machine, mining stirred tank, feeding machine, concentrator, mine hoist, mine conveyor, pre-water-ball plate, spiral chute, beneficiation shaker and washing machine, etc.

Technical Data

| Specification Model |

Effective cubage (m³) |

Processing capacity (m³/min) |

| XJK-0.35 | 0.35 | 0.18-0.4 |

| XJK-0.62 | 0.62 | 0.3-0.9 |

| XJK-1.1 | 1.1 | 0.6-1.6 |

| XJK-2.8 | 2.8 | 1.5-3.5 |

| XJK-5.8 | 5.8 | 5-7 |

| SF-0.37 | 0.37 | 0.2-0.4 |

| SF-0.7 | 0.7 | 0.3-0.9 |

| SF-1.2 | 1.2 | 0.6-1.6 |

| SF-2.8 | 2.8 | 1.5-3.5 |

| SF-4 | 4 | 2-4 |

| SF-8 | 8 | 4-8 |

| SF-10 | 10 | 5-10 |

| SF-20 | 20 | 5-20 |

| JJF-2 | 2 | 1-3 |

| JJF-4 | 4 | 2-4 |

| JJF-8 | 8 | 4-8 |

| JJF-10 | 10 | 5-10 |

| JJF-16 | 16 | 5-16 |

| JJF-20 | 20 | 5-20 |

Quick Way To Get Price

Tell us your needs, there will be more favorable prices!